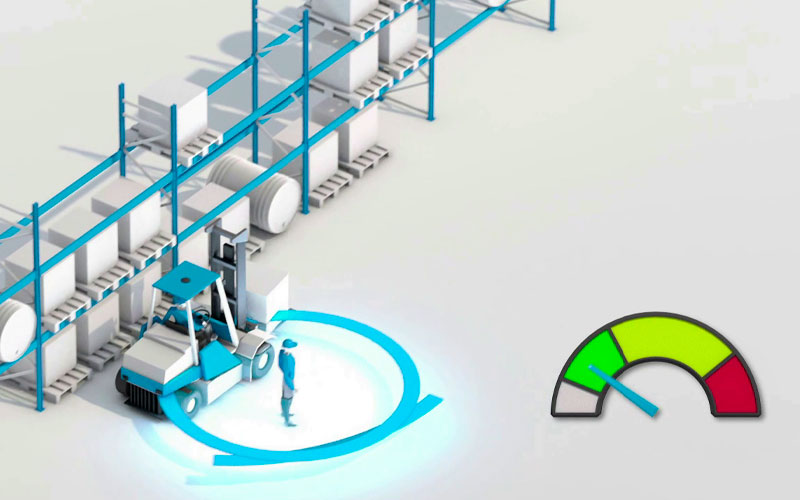

Active Reverse System

Every vehicle has a blind spot, a space surrounding the vehicle which the driver can’t see. This can impact the forklift driver and decrease site safety and in return increase the likelihood of an accident. Due to these invisible spaces, vehicles and/or objects can be damaged or people can get injured.

Our Active Reverse System has been designed to provide the driver with accurate information about the free space in front, behind and to the side of the forklift truck. The information the driver now has will help him to work and move around the warehouse safely. As they can see the free space around them this will reassure the driver of his immediate surroundings. To add another layer of safety we can also integrate Active Reverse with our iTEch speed control to slow the truck down when it reaches a set distance away from an object.

How it works

Our Active Reverse solution works through ultrasound, with sensor units mounted on the top, sides and rear of the vehicle. These sensor units scan the space behind for a distance between 10cm and 9m. This space is divided into three zones, each with its own visual and acoustic signal.

Active Reverse activates when the driver changes into reverse and performs a self-test. Within a few seconds, the system is ready.

Key features include:

- Utilises ultrasound sensor units mounted at the rear, sides and top of the vehicle to scan space behind the vehicle and to protect against rear/tail-swing accidents

- Covers a distance from 10cm to 9m – space is divided into 3 zones, each with their own visual and acoustic signal

- Unit mounted in cabin warns driver utilising LED signals and audible tones

- Automatically activates upon selecting reverse gear.

Benefits

- Improve site safety

- Reduce vehicle, stock and environmental damage

- Better driver confidence

- Not affected by bad weather or darkness

- Especially useful on large forklifts, container handlers or loaders, or any vehicle with a poor/restricted view from the cabin.

Need more info?

Contact Us

For further assistance or to request a quote, please fill out the form below.

Related Products

Forklift Proximity Warning Systems

Our Forklift Proximity Warning Systems improve safety within a warehouse, production or manufacturing facility by alerting forklift operators to any nearly hazards, such as personnel or stock items placed within the area.

iTEch Forklift Control Unit

The Transmon iTech Forklift Control is a singular unit that combines multiple functions all from the same unit, including Road Speed Control, Tyre Wear Reduction, Engine Idle Shutdown and Auto Shift Control.