Implementing Technology to Balance Speed & Safety in Port Operations

Forklifts and material handling equipment (MHE) continue to offer a reliable and practical solution for the movement of goods in and around ports and dockside environments. As the backbone of port logistics, they enhance the process of moving containers, pallets, and materials to maintain efficiency and throughput of a high volume of goods. But in high-traffic, zone-diverse environments like ports, allowing forklift speed to go unmanaged can cause collisions, injuries, and damage to vehicles, goods, pedestrians, and infrastructure.

Globally, forklift accidents represent a significant safety concern. An OSHA (Occupational Safety and Health Administration) report states that forklift truck accidents cause about 34,900 serious injuries each year in the United States, while in the UK, forklifts account for around 85 fatalities annually, with 9,000 workplace injuries every year.

These figures highlight the significant potential risks associated with forklift trucks and strongly support the case for deploying speed control and other technology safety solutions for port and maritime material handling activities, ensuring a safe working environment for drivers and pedestrians.

The Need for Speed Control

It may seem common sense, but enforcing speed limits in critical areas has a significant impact not only on driver and worker safety, but also on productivity and the environment. Some of the key reasons for speed limits to be enforced around port operations include:

- Pedestrian Safety: Lower speeds reduce stopping distances, which reduces the risk of collisions with pedestrians.

- Mitigating Property Damage: Slower vehicle operation minimises damage to equipment and goods.

- Environmental & Maintenance Benefits: Reduced speed lowers fuel or electricity use, emissions, tyre wear, and engine strain, extending the lifespan of forklifts and MHE.

Effective speed management across all port operations, both in a storage warehouse and externally around the docks, supports best practice for safe operations and offers a reliable solution to regulating speed that could cause injury or damage to goods if disregarded.

UK Guidelines & Port Recommendations

According to the HSE and industry champion, the UK Material Handling Association (UKMHA), a standard maximum speed of 5 mph (8 km/h) is advised in warehouses, reducing to 3 mph (5 km/h) in pedestrian-heavy zones. While ports may permit slightly higher speeds in open outdoor areas, safety in these areas remains critical for safe operations.

Developing a Safety Strategy for Port Operations

With safety of paramount concern, there are a number of key steps managers can take to devise and implement a comprehensive safety strategy for port operations.

- Zone Mapping & Risk Assessment: Identify areas where speed poses risks, creating dedicated speed zones for various areas, e.g. quayside or container yard, based on traffic & pedestrian flow and the element of risk.

- Safety solutions for integration: Identify and deploy safety-enhancing systems for integration, such as speed control, collision avoidance, cameras, and access control.

- Training: Create and implement a comprehensive safety training programme to ensure operators and pedestrians are fully briefed on operational procedures.

- Monitor & Improve: Use integrated systems such as impact detection logs and fleet management data to review zones and compliance, making upgrades and enhancements as required.

Through the comprehensive detailing of all these areas, managers can create and implement best practice procedures across all port operations, enhancing safety and productivity, and ensuring forklifts and material handling equipment operate at an optimal level with minimal downtime needed due to unplanned maintenance.

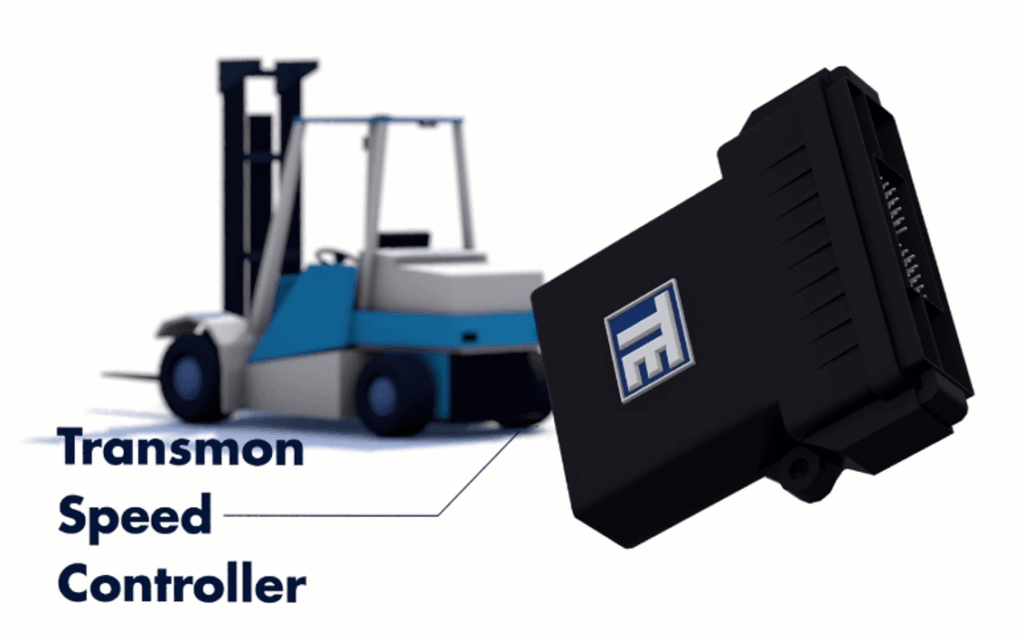

Technology Solutions by Transmon for Safer Port Operations

As part of a comprehensive safety strategy, managers can integrate a wide range of advanced features into their fleet of forklifts and MHE. Transmon Engineering offers a suite of safety-enhancing systems and solutions ideally suited to high-volume operations and can be tailored for speed control in mixed-zone environments such as ports, loading docks, or container yards.

1. Speed Control Systems

Forklift speed limiters and adaptive controllers enforce site speed limits by automatically reducing vehicle speed in designated zones with no loss of power or productivity. Port operations can create dynamic zones, such as reducing speed from 10 mph (16 km/h) to 5 mph (8 km/h) near quay edges or pedestrian areas.

2. Dynamic Speed Management

Integrating Radar Speed Zoning, Speed Safety Zones, and Safety Protection Zones, Transmon’s solutions equip port operations with responsive speed regulation. As forklifts enter a danger zone, speed is instantly capped, and once they leave the zone, normal speed can resume.

3. Collision Avoidance & Proximity Warning

Transmon’s ACAS (Active Collision Avoidance System) combines sensors with its own speed limiters to offer a complete package for forklift trucks: recognising potential danger, alerting the driver, and automatically slowing the vehicle.

Proximity warning systems feature a vehicle-based antenna system that generates a 360˚ detection zone around the vehicle, enabling the detection of nearby personnel or vehicles and alerting the driver to help avoid potential incidents.

4. Access Control & Impact Detection

Pin-code keypads & fleet management systems ensure only trained operators use the forklifts, whilst the iTEch Impact Detection system logs collisions and alerts supervisors, prompting accountability and corrective measures.

From speed zones to proximity warning systems, integrating forklift fleets with a range of safety enhancement systems can significantly impact worker safety and productivity, resulting in enhanced operations and compliance with strict safety working practices.

Routine Safety Checks and Proactive Maintenance

In addition to creating a thorough port safety strategy and integrating key safety technologies, regular safety inspections and proactive maintenance are essential to supporting continued safe forklift operations at ports. From daily visual inspections to detailed maintenance, implementing safety procedures ensures that both the machinery and operators are working within optimal safety parameters.

Daily Safety Checklists

Operators should perform a pre-shift inspection every day to identify potential faults before a forklift is used. A standard forklift checklist includes visual inspection of components such as tyres, forks, overhead guards, and signs of fluid leaks. In line with manufacturers’ guidelines, operational checks should be made to key features such as brakes, lights, and any integrated speed or collision avoidance systems to ensure all are working efficiently. Additionally, safety equipment, including seat belts and mirrors, as well as power sources, should be checked to ensure they are suitably secure and charged for operation.

To further streamline reporting with options to flag urgent maintenance needs, safety checks can be digitised using technologies such as handheld devices or onboard fleet management systems. This enables a record of all checks made, their level of suitability, and the opportunity for immediate notification of any area of the forklift that may need urgent attention or be deemed unsafe for use.

Scheduled Maintenance Protocols

Implementing a structured maintenance schedule helps prevent mechanical failures that could lead to accidents or downtime, affecting worker safety and productivity.

Port managers should ensure that manufacturer-specified service intervals are followed for oil changes, hydraulic checks, and component replacements. Monitoring systems provide notification through integrated sensors of any detected wear and tear or anomalies in temperature, vibration, pressure, and fluid levels. These maintenance logs can be integrated with fleet management software for complete transparency and to support compliance audits.

By implementing a comprehensive and proactive maintenance schedule, port operators can reduce potential downtime, extend the lifetime of the equipment, and meet HSE and industry safety standards. Combining routine safety checks with smart maintenance practices enables port facilities to enhance the reliability of their forklift fleet, reduce operational risk, and support a culture of accountability.

Conclusion

Management of forklift trucks and other MHE remains critical at ports, helping to strike a balance between rapid throughput and safe operations. With Transmon’s range of solutions, such as adaptive speed control, collision avoidance, impact detection, and access control systems, ports can significantly reduce accidents, save costs, and maintain compliance with industry standards.

For a tailored assessment of operational requirements, contact Transmon Engineering on +44 116 260 4200 or sales@transmon.co.uk.