Choosing the right forklift type for your operations is more than just selecting the cheapest option available. As it can have direct and major implications for cost, safety, productivity, environmental impact and worker comfort, the selection process requires a considered and detailed approach.

At first glance, an electric forklift may offer lower emissions and quieter operation, while a diesel model could handle tougher terrain and heavier loads. However, the key is matching the forklift’s strengths to your operational needs.

Our latest article highlights the main factors that influence the decision between electric versus diesel forklifts, compares performance, looks at the advantages & disadvantages of each, explores safety considerations, and offers guidance for how to make the right choice for your operation.

Key Factors That Influence the Electric vs Diesel Decision

When choosing between electric and diesel forklifts, several crucial factors must be assessed to ensure you select the right option for your needs.

These include the operational environment, whether your forklifts will be used primarily indoors or outdoors, load and lifting requirements, and where electric models can access charging facilities. The total cost of ownership, compliance with regulatory standards, and safety concerns such as noise levels, driver and pedestrian visibility, and the risk of collisions, should all inform your decision.

The Difference Between Electric vs Diesel Forklifts

Let’s explore how each forklift type operates and examine the key differences that will impact your decision.

How They Operate

The primary difference lies in how each forklift type generates power:

- Electric forklifts are powered by electric motors and use rechargeable batteries. Batteries can be recharged in situ or removed/swapped over in the case of multi-shift working or cold-store environments.

- Diesel forklifts use internal combustion engines, running on fossil fuels. They need a fuel supply and have additional component parts e.g. engine, transmission, etc.

Top-Level Differences That Impact Performance and Suitability

Some of the biggest differences include:

- Emissions: Electric = zero at point of use; diesel = exhaust gases, particulates.

- Noise: Electric forklifts are much quieter; diesel forklifts are louder, with more vibration.

- Running/refuelling/charging time: Diesel can be refuelled quickly; electric forklifts need charging, which can take several hours (though fast charging helps to lower typical charging times). Li-Ion offers short recharge times and opportunity charging.

- Terrain & load: Diesel forklifts tend to have higher torque, better performance in rough/or outdoor conditions; electric forklifts work well indoors, with smoother surfaces and in tighter spaces.

- Maintenance: Electric forklifts have fewer moving parts, requiring less maintenance, whereas diesel forklifts need more frequent servicing (e.g. for filters, oil, fuel systems).

Performance Comparison: Electric vs Diesel Forklifts

| Metric | Electric Forklifts | Diesel Forklifts |

|---|---|---|

| Power / Lifting Capacity | Sufficient for many indoor, medium-to-light loads; may lag for very heavy or continuous large loads. | Stronger for heavy loads; better torque; more suitable for lifting large or awkward loads, steep inclines or outdoor sites. |

| Runtime / Duty Cycle | Limited by battery life; need downtime for charging or swapping batteries. Duty cycle depends heavily on battery technology and charger availability. | Can run as long as fuel supply; refuelling is quick; more suited for continuous heavy-duty outdoor shifts. |

| Operational Efficiency | Electric motors are more energy efficient, quieter in operation, and better suited for controlled environments. | Diesel engines create emissions; fuel cost fluctuates; performance may be impacted under certain conditions (e.g. extreme low temperatures). |

| Maintenance Requirements & Costs | Generally lower: fewer moving parts, less frequent servicing. Up-front battery purchase and replacements can be costly. | More frequent maintenance: engine servicing, fuel system, exhaust, filters, oil, belts, etc. But diesel units can be rugged, built for tough operations. |

Electric Forklift Advantages & Disadvantages

While electric forklifts offer several compelling benefits, it’s important to weigh these against their limitations to determine if they’re the right fit for your operation.

Benefits of Electric Forklifts

- Lower emissions: Zero exhaust emissions, supports cleaner indoor air. Contributes to a company’s lower carbon footprint.

- Quieter operation: Less noise, less vibration. Better for operator comfort and for noise-sensitive environments.

- Reduced maintenance: Fewer components to become faulty and maintain.

- Operational efficiency: Smooth torque, good control, often lower running cost per hour.

Limitations of Electric Forklifts

- Charging time/downtime: Time required to recharge; you may need multiple batteries or fast-charging infrastructure.

- Higher initial cost: Especially battery cost and charging equipment.

- Battery replacement & lifespan: Batteries degrade over time; replacing them can be costly. Also, performance may reduce towards the end of the battery’s life.

- Outdoor/harsh environment issues: Weather exposure, extreme temperatures, and rough ground can affect performance.

Ideal Applications for Electric Forklifts

- Indoor warehouse operations and where air quality needs to be clean.

- Production areas requiring low-noise working environments.

- Retail environments, distribution centres with regular operating hours and controlled conditions.

- Operations with frequent start-stop and repetitive handling, where the electric forklifts’ smoother control helps.

- Environments concerned about sustainability, emissions, and noise (e.g., near residential areas or where regulatory limits apply).

Diesel Forklift Advantages & Disadvantages

Understanding the benefits and limitations of diesel forklifts will help you determine whether they’re the right choice for your specific operation.

Benefits of Diesel Forklifts

- Longer runtime and quick refuelling: Refuel in minutes, no long waiting for a battery charge. Best for long shifts or continuous outdoor work.

- Outdoor capability & ruggedness: Good performance on uneven terrain, under varying weather conditions. Diesel engines are robust and powerful, ideal for heavy-duty working environments.

- High lifting capacity/torque: Better for heavy loads, or high lifting/storage of goods.

Limitations of Diesel Forklifts

- Emissions & air quality: Produces exhaust gases, particulates; may require ventilation indoors; stricter regulatory constraints.

- Noise & vibration: Quieter electric machines offer better operator comfort; diesel tends to be louder.

- Fuel costs & volatility: Diesel fuel prices fluctuate; over time, fuel costs may become a cost barrier.

- Higher maintenance: More complex engine, exhaust, filters, etc., leading to more wear and tear.

Ideal Applications for Diesel Forklifts

- Outdoor operations such as construction sites, shipping ports, and yards.

- Operations requiring extended runtimes without frequent access to charging.

- Remote locations where electrical infrastructure or charging capability is limited.

- Situations with heavy loads, steep ramps or rugged surfaces.

Cost Analysis: Electric vs Diesel Forklifts

Beyond performance, the financial implications of each forklift type vary across purchase price, running costs, and long-term maintenance:

- Initial Purchase Price: Diesel forklifts are usually less expensive up front than electric forklifts, when you factor in the cost of batteries, charging infrastructure, etc.

- Operating Costs: Electric models tend to have lower energy cost per hour (electricity tends to be cheaper than diesel per unit of usable power) and require lower maintenance. Diesel tends to have higher fuel & service costs.

- Maintenance & Replacement Costs: Electric needs battery replacements after years; diesel needs more frequent servicing of engine, filters, etc. Over a lifetime, electric forklifts may prove more cost-effective for many typical indoor or mixed‐use operations.

Emission Regulations Affecting Diesel Forklifts

In addition to the general costs of owning and running a fleet of forklift trucks, there are further environmental factors that may affect the overall operational costs.

One such environmental regulation is enforced by the EU, designed for diesel-powered Non-road Mobile Machinery (NRMM). It imposes limits on pollutants such as carbon monoxide, hydrocarbons, NOx, and particulate matter, covering a wide range of machinery, from forklifts to generators. Stage 1 was launched in 1999, with Stage V coming into force on 1st January 2020, which has lowered particle emissions from an initial 0.54 to 0.015 grams per kilowatt hour. This reduction has been achieved mainly through the adoption of more modern particulate filters.

Meeting the stringent requirements of Stage V typically requires the use of advanced exhaust technologies. This, in turn, affects the cost of diesel forklifts, as models compliant with Stage V are generally more expensive than their predecessors. However, while these technologies may increase upfront costs, they enable companies to benefit from significantly lower fuel consumption in the latest generation of machines.

Safety Considerations for Both Forklift Types

When it comes to forklift operations, safety is paramount, regardless of forklift type. Choosing between electric and diesel forklifts involves many safety features and considerations, including:

Safety Features & Requirements

- Exhaust/fume management: Diesel forklifts produce emissions that, indoors, can impair air quality; require ventilation or emission control.

- Noise & vibration: High noise levels can reduce operator alertness and communication; electric models are quieter.

- Visibility: Lighting, cameras, and mirrors matter especially in outdoor or low-light conditions.

- Speed control: Controlling forklift speed, especially in areas with pedestrians or in tight zones, is crucial.

- Collision/impact detection: Sensors to detect when a forklift strikes something or someone; logging capacity; automatic alerts or shutdowns.

- Access control: Who is allowed to operate, schedule maintenance, and ensure operator training.

Transmon Engineering’s Safety-Enhancing Systems

Transmon Engineering offers a range of safety-enhancing systems and solutions that are highly effective when integrated with either electric or diesel forklifts:

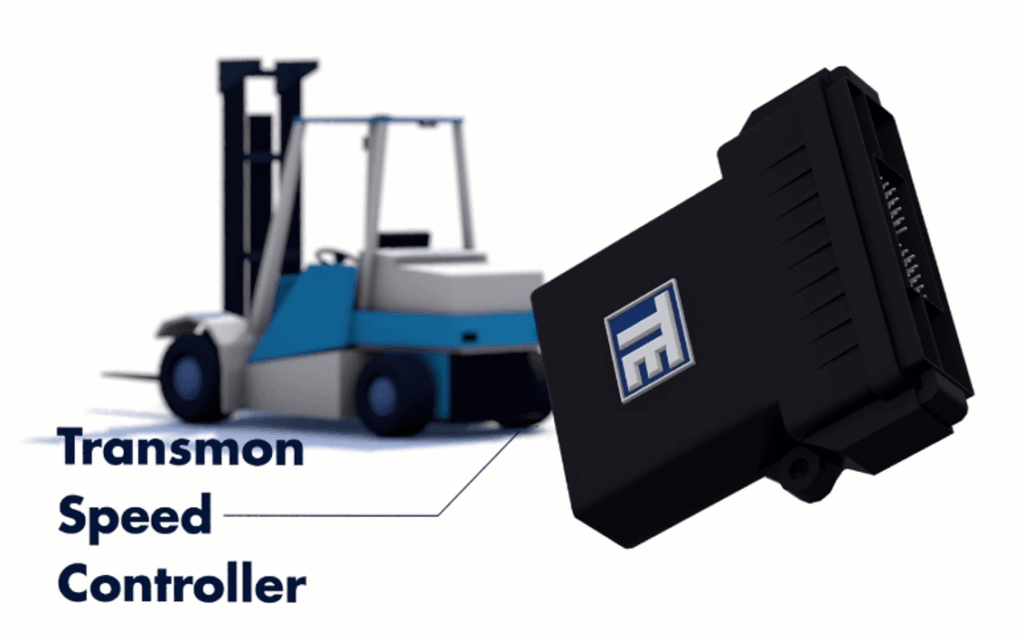

- Speed Control: Transmon’s speed controllers, forklift speed limiters and speed zoning systems enable setting maximum speeds for forklifts, especially in zones with higher pedestrian traffic or hazards.

- Site Safety / Impact Detection: The iTEch Standalone Forklift Impact Detection system records the highest level of impact and the quantity of impacts, triggering audible and visual alarms or even shutdowns.

- Access Control: Ensuring only authorised, trained operators can use forklifts, through integrated keypads or other forklift access control systems.

- Idle Timeout: Automatic Idle Timeout can help to enforce access control when MHE is left idling without a driver seated.

- Cameras: Forklift cameras can be mounted to improve visibility, particularly useful across indoor and outdoor operations, where loads obscure the driver’s view or building infrastructure, such as narrow aisles, heightening the visible difficulty

These safety-enhancing systems can help mitigate the operational and collision risks associated with either type of forklift truck.

Making the Right Choice for Your Operation

Here are some guidelines to help decide which forklift type suits your individual operational needs:

Key Factors to Consider

- Environment: Is most of the work indoors or outdoors? How well-ventilated are indoor spaces? What about weather exposure?

- Load requirements: What weight of goods are you lifting, how high, on what surfaces (smooth floor vs rough terrain)?

- Duty cycle and scheduling: How many hours per shift? Can you afford downtime for charging (for electric) or fuel supply issues (for diesel)?

- Infrastructure & energy access: Can you provide the required battery charging infrastructure, and what is the cost of electricity or the benefits of renewable energy?

- Regulatory constraints & sustainability goals: What are the emissions regulations, carbon reduction targets, and local noise restrictions?

- Total cost of ownership: What is the initial purchase price, and likely energy/fuel costs, maintenance, and impact on downtime?

Application-Specific Recommendations

- If you run a large indoor warehouse with many hours of operation, electric may deliver better ROI over time, plus the non-monetary benefits of lower emissions and a quieter environment.

- For heavy loads or environments with uneven ground, outdoor weather, or sites without good power/charging infrastructure, diesel may be more practical.

- Hybrid or mixed fleets can also make sense: using electric for indoor and light-duty material handling, and diesel for heavy and/or outdoor operations.

The Future Trend

Electric forklift technology is improving through enhanced battery technology, faster charging, longer battery life, etc., alongside environmental regulations which are increasingly pushing businesses toward reduced emissions. As the cost of electric forklifts becomes more attractive and charging infrastructure improves, operating an electric fleet will become even more advantageous. Many operations are likely to gradually shift toward electric or at least reduce the reliance on diesel forklifts.

Summary

- There is no one-size-fits-all answer to whether you should choose diesel or electric forklift trucks. The right selection of forklift depends on your workload, environment, budget, and safety needs.

- Electric forklifts tend to offer benefits in emissions, quieter operation, lower maintenance, and better suitability for indoor use, but come with higher upfront costs and challenges around charging and battery life.

- Diesel forklifts excel in outdoor, rugged, heavy-duty applications where long continuous runtime is needed, and where the infrastructure or environmental constraints make electric less practical.

How Transmon’s Solutions Support All Forklift Types

Transmon Engineering’s range of safety-enhancing solutions is compatible with both electric and diesel forklifts. These include speed control and zoning systems designed to minimise risk in high-hazard or pedestrian areas, impact detection technology to identify potential collisions early and enhance accountability, access control measures that ensure only properly trained and authorised personnel operate the equipment, as well as cameras and other visibility aids which improve operator awareness where sightlines may be restricted by loads or terrain.

Collectively, these technologies address many of the safety concerns associated with both types of forklifts, while also enhancing productivity and extending equipment lifespan.

How to Start the Selection Process – Electric vs Diesel

If you’re evaluating your forklift fleet, here are immediate steps you can take:

- Conduct an audit of your operations: hours, weights, indoor vs outdoor, shift patterns.

- Estimate total cost of ownership for both electric and diesel over a realistic time horizon (e.g. 5-10 years), including fuel/electricity, maintenance, and downtime.

- Conduct a safety risk assessment of your current operations and investigate how systems such as Transmon’s speed control, impact detection, access control, and cameras could enhance safety and productivity, while reducing costs.

- Explore test trials or pilot programmes: try electric models in part of your fleet, assess how they perform in your environment.

Once you have assessed your individual needs and identified the associated costs, you are on the road to a strategic purchase that will add value to your business and deliver material handling efficiency that meets your individual operational, cost, safety, environmental and regulatory needs.

We offer safety solutions for both electric and diesel forklifts. Get in touch with Transmon Engineering today. Contact one of our experts by calling 0116 260 4200.