Forklift safety remains a top priority across all industrial and warehouse settings. One of the most effective yet often overlooked tools for enhancing on-site safety is the use of forklift warning lights. These lights not only help protect personnel, equipment, and building infrastructure but also ensure compliance with industry regulations. In this article, we’ll explore the different types of forklift warning lights, their specific uses and meanings, and how to select the right lighting system for your operation.

The Importance Of Understanding Forklift Warning Light Meanings

Forklift warning lights play a vital role in workplace safety. Understanding their meanings and proper use ensures a proactive approach to forklift accident prevention.

Safety Requirements

Regulatory bodies such as the HSE (for the UK) and OSHA (for the US) stress the importance of visibility and hazard awareness in environments where heavy machinery operates. For countries such as Mexico, the government has created mandatory technical regulations for material handling and storage in workplaces such as warehouses and distribution centres to protect workers and prevent damage to the facilities.

Forklift lighting systems, especially visual indicators such as warning lights, are a vital part of supporting best practice. Overall, operators are responsible for maintaining a safe working environment, with lighting and visibility for drivers and pedestrians being part of this scope.

Incident Prevention and Operator Awareness

Forklift warning lights serve as immediate, visible cues to other workers in the vicinity. They alert pedestrians and other equipment operators of a forklift’s presence, direction of travel, or an impending hazard. This dramatically reduces the risk of collisions, especially in blind corners or high-traffic areas. Learn more about forklift blind spot safety strategies.

Additional Benefits of Warning Lights

- Increased operator confidence and control

- Improved pedestrian awareness in shared workspaces

- Enhanced operational efficiency in low-visibility conditions

In addition to improving operator control and pedestrian safety, warning lights provide a robust, reliable, and long-lasting solution to achieve enhanced levels of safety in a warehouse, depot, or production facility environment. Explore our full range of forklift warning light systems.

Common Types of Forklift Warning Lights & Their Meanings

In modern industrial environments, forklift warning lights are essential components of a wider safety system. These lights come in various forms, each designed to communicate specific messages and improve situational awareness for both operators and pedestrians.

With the rise of automation, tighter health and safety regulations, and increasingly busy warehouse layouts, visual alerts have become indispensable, helping to reduce blind spot accidents, signal directional movement, and mark out safe zones. From bright LED spotlights to intelligent automated beacon systems, each light has a distinct role in enhancing visibility and minimising the risks associated with operating forklift trucks.

In the following section, we’ll showcase the most common types of forklift warning lights, explain their functions and applications, and highlight how they can be integrated into smarter, sensor-based safety systems. Whether you’re retrofitting existing equipment or specifying lights for a new fleet, understanding these warning light categories is key to selecting the right setup for your operation.

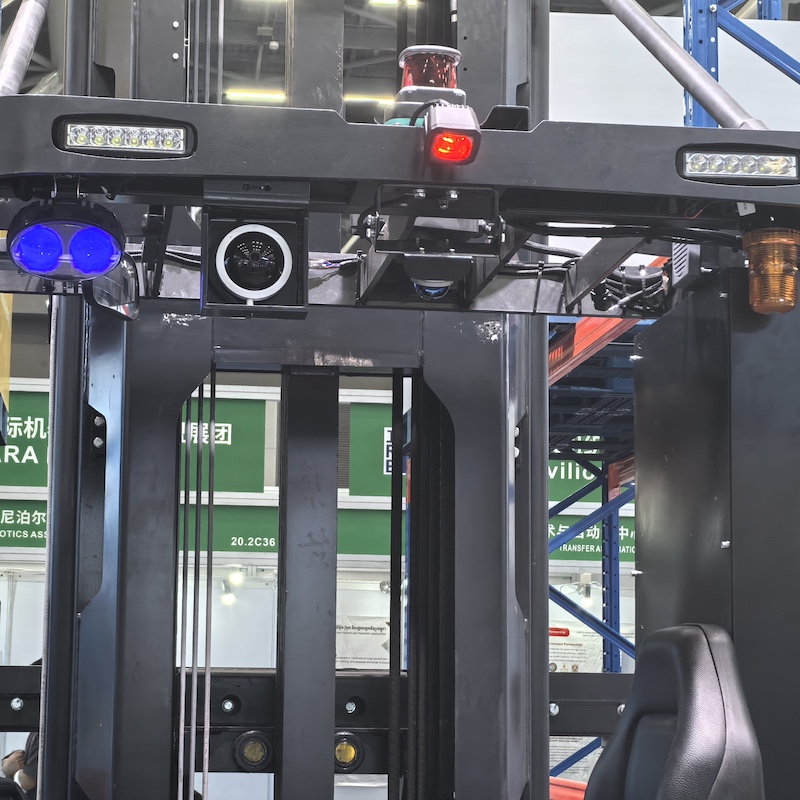

Blue LED Spot Alert Lights

Blue LED spotlights project a vivid circle or dot on the ground a few meters in front or behind the forklift and are often activated in accordance with the direction of travel. This effectively creates a moving safety zone in front or behind the forklift, alerting pedestrians and other vehicles of a moving forklift’s approach, before it arrives. Blue Spot Warning lights can also be integrated with other safety technologies, such as proximity warning systems for automatic activation. Learn more about blue LED spot alert lights.

Red LED Spot Alert Lights

Red LED spotlights work similarly to blue spotlights but offer even higher visibility in certain environments due to a more intense colour, providing a strong visual alert, ideal for high-traffic zones or areas with low lighting requirements. However, floor colour can influence the effectiveness of both red and blue spotlights; therefore, the selection of light colour should always be based on the environment.

As with blue LED spotlights, red spot alert lights work well in combination with sensor-triggered safety systems, such as proximity warning technology. Learn more about red LED spot alert lights.

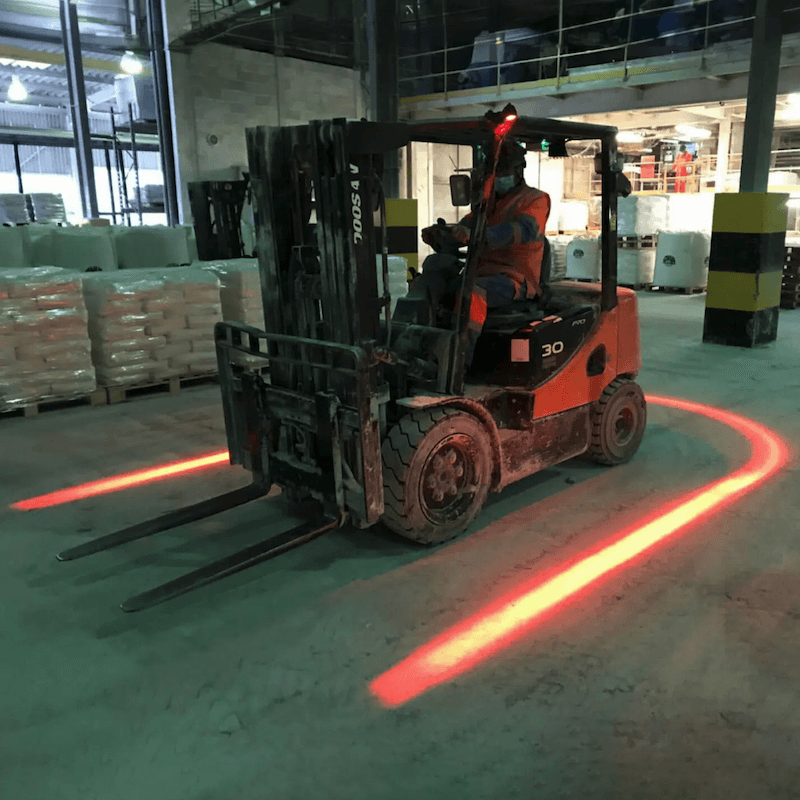

Red LED Line Alert Systems

Red line alert lights project a solid line on the floor, acting as a visible “no-go” safety boundary for pedestrians. They are designed to create a buffer zone around the forklift for pedestrians to avoid, with lights positioned on one or multiple sides of the forklift truck for complete line coverage. They are often used to highlight the minimum Truck-to-Pedestrian safety distances. Explore our Red LED Line Alert systems.

Beacon Alert Systems

Simple yet highly effective, beacon lights are rotating or flashing lights mounted on top of forklifts. They warn pedestrians and other forklift drivers of forklift activity, especially when starting, reversing, or turning. Beacon lights can create a continuous flash during operation to signal the forklift’s presence, or more advanced solutions can be activated by impact detection technology. When the system senses that impact level thresholds are exceeded, it triggers a visual and audible alert, which may require a supervisor override to reset. Discover Transmon’s advanced TE Forklift Impact Detection system.

Other Types Of Forklift Warning Lights

In addition to Transmon’s comprehensive portfolio of forklift warning lights, the following warning lights can be integrated into forklift fleets for additional safety:

- Green Safety Lights: Indicate safe approach zones or confirm forklift is under safe operation

- Directional Arrow Lights: Project arrows to indicate turning direction or travel path

- Headlights and Brake Lights: Standard vehicle-type signals to indicate movement intentions

- Laser Lights: Indicate the precise path the forklift will take to aid operators in forklift positioning

These additional lighting options, when used alongside Transmon’s core solutions, can further enhance visibility, improve operator precision, and contribute to a safer, more controlled working environment.

Overhead Crane Lights

While not exclusive to forklifts, crane-mounted warning lights play a significant role in shared workspaces where forklifts and overhead cranes operate. These lights are used to mark out crane paths on the ground to prevent forklifts from entering active lifting zones. This helps forklift operators to maintain an awareness of potential overhead hazards, which reduces the risk of a collision.

Choosing the Right Warning Light System for Your Operation

Selecting the appropriate warning light solution for your operational needs depends on a variety of factors, including:

- Operational Environment: Indoor vs outdoor facilities, ambient lighting, and floor surface reflectivity

- Noise Levels: Visual alerts are critical in noisy environments where audio alarms may be missed

- Forklift Type & Usage: Counterbalance forklifts, reach trucks, or powered pallet jacks may require different configurations

- Workforce Awareness: Consider proximity detection and automatic activation for environments with high pedestrian traffic

A comprehensive safety solution will often include multiple lighting systems working together, but it’s important to ensure that over-lighting does not cause a detrimental effect on either safety or productivity. Having too many lighting systems fitted may detract from the most effective solution, so consideration must be given to their application. As an example, using directional warning lights can be more impactful than having numerous lights fitted to a forklift that could blind pedestrians in the vicinity, affecting both safety and effectiveness.

Regardless of the warning solutions chosen, proper training and awareness campaigns must be implemented throughout the business. Both forklift operators and employees must fully understand the purposes of these forklift safety lights to make the workplace safer and lower the risk of accidents and injuries.

Summary

Understanding forklift warning light meanings not only supports best practice, but it is a critical part of maintaining a safe, compliant, and efficient workplace. Each type of warning light serves a distinct purpose, from alerting nearby personnel to preventing accidental collisions.

By combining Transmon’s cutting-edge warning lights with additional safety technologies such as ACAS (Advanced Collision Avoidance System), Speed Control Systems, and Access Control Solutions, fleet operators can create a comprehensive, layered approach to forklift safety.

Ready to enhance your site safety? Get in touch with Transmon Engineering today. Contact one of our experts by calling 0116 260 4200.