Tuesday 10th June brings us this year’s National Forklift Safety Day (NFSD), a pivotal initiative led by the UK Material Handling Association (UKMHA).

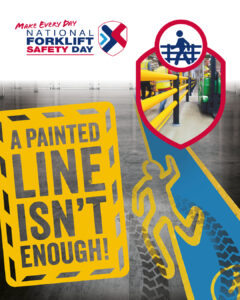

With a powerful strapline of ‘A Painted Line Isn’t Enough’, this year’s campaign underscores the human cost of forklift-related accidents, emphasising the critical need for enhanced safety measures in material handling operations.

Why Focus on Forklift Safety?

Forklifts continue to be indispensable in warehouses and industrial settings, yet they pose significant risks. Statistics show that forklift incidents result in numerous injuries and fatalities annually, often due to collisions with pedestrians, other equipment, or building infrastructure. NFSD serves as a poignant reminder for businesses of all sizes that focus is needed to assess and reinforce their safety levels to protect workers and assets.

Transmon Engineering – Championing Safety Innovations

Transmon Engineering has been at the forefront of forklift safety solutions for over 25 years. Specialising in advanced driver assistance, safety, and control systems, we design and install innovative technologies that significantly enhance workplace safety and reduce the risk of collisions and accidents.

Key Safety Solutions Supporting the NFSD Initiative

- Proximity Warning Systems: Use advanced sensors to detect nearby pedestrians and obstacles, alerting operators to potential hazards.

- Active Collision Avoidance Systems (ACAS): automatically slow down or stop forklifts when a collision risk is detected, enhancing response times and preventing accidents.

- Speed Control Solutions: Implement site-specific speed limits for forklifts, ensuring consistent and safe operating speeds throughout the facility.

- Access Control Systems: Restrict forklift operation to authorised personnel through pin code keypads, enhancing accountability and reducing unauthorised use.

- Fleet Management Systems: Monitor and manage forklift usage, maintenance schedules, and operator performance to optimise safety and efficiency.

Proud to be a UK manufacturer, our safety solutions are designed to withstand the demanding conditions of material handling environments. Our commitment to innovation and quality has made us a trusted partner for businesses aiming to enhance workplace safety.

Aligning with National Forklift Safety Day

At Transmon Engineering, we actively support NFSD each year by providing solutions that align with the campaign’s objectives. Our technologies not only mitigate risks but also support the growth of a safety-first culture within organisations. By integrating our sensors and systems, companies can demonstrate their commitment to employee well-being and operational excellence.

Taking Action: Enhancing Safety in Your Facility

- Conduct Safety Audits: Assess current safety measures and identify areas for improvement.

- Implement Advanced Technologies: Adopt systems to proactively address safety concerns.

- Train Employees: Ensure all staff are educated on safety protocols and the proper use of equipment.

- Engage with Industry Initiatives: Participate in NFSD events and stay informed about best practices in material handling safety.

By taking these steps, organisations can significantly reduce the risk of accidents and create a more collaborative working environment, one that safeguards drivers, pedestrians, inventory, and building infrastructure now and for years to come.

Building A Complete Warehouse & Forklift Traffic Safety Strategy

When addressing warehouse traffic to improve forklift and pedestrian safety levels, warehouse operators should focus on creating an integrated, layered approach, rather than hoping one solution will provide the answer. From route planning and speed control to advanced visibility and collision prevention systems, each technology tool plays a critical role within a comprehensive warehouse traffic management strategy.

By combining advanced, intelligent technologies such as camera systems, warning lights, and proximity sensors, with speed and lift height zoning, you can create a safer and more responsive warehouse environment where the risk of accidents is minimised, and material handling productivity remains optimised.

Transmon Engineering is fully committed to helping warehouse operations of all sizes implement industry-leading MHE and forklift safety solutions to meet today’s safety standards, and beyond.

Get in touch with us today to discover how we can help elevate your warehouse safety strategy, finding the right balance between safety and productivity. Contact one of our experts today by calling 0116 260 4200.